Our Services

Comprehensive quality testing and inspection services designed to ensure your products meet the highest standards of safety, quality, and compliance.

Conventional Services

Ultrasonic Testing

High penetration power, allowing for flaw detection deep within a part. High sensitivity, allowing for the detection of very small flaw scan be used to test when only one side of an object is accessible Greater accuracy, when compared to other non-destructive testing methods, for determining depth of intemal flaws and the thickness of parts with parallel surfaces. • Able to estimate size, shape, orientation and nature of defects. Able to estimate alloy structures of components with differing acoustic properties. Non-hazardous to nearby personnel, equipment or materials. Highly automated and portable operations possiblelmmediate results can be obtained.

Radiography Testing

Industrial radiography is a non-destructive testing (NDT) method of inspecting the quality and integrity of materials for hidden flaws by using the ability of short wavelength electromagnetic radiation (high energy photons) to penetrate various materials. Commonly, RT is performed using two different sources of radiation which are X-ray and Gamma ray. Provide permanent visual image of the test object. The results of inspection can be reviewed at any time. Applicable to almost all materials.

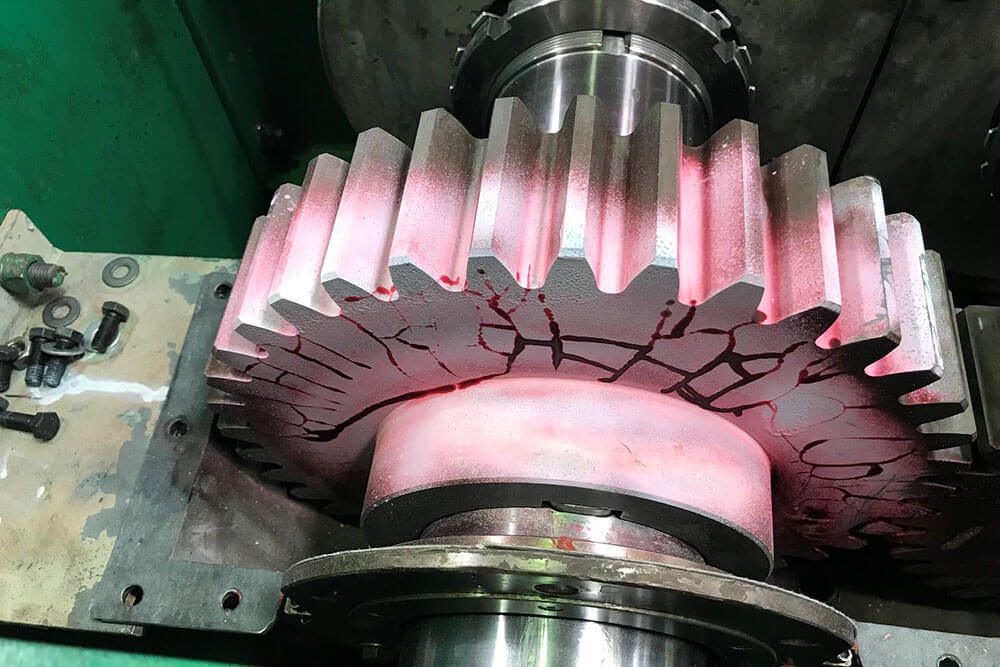

Liquid Penetrant Testing

Liquid penetrant testing is a versatile nondestructive test method used for the detection of OPEN TO SURFACE DISCONTINUITIES in a wide variety of solid, non-porous materials. This method is also known as dye penetration testing. It is economical, versatile, and requires minimal training when compared to other NDE methods. Fast turnaround time High sensitivity Flaws are visually indicated on surface Appropriate for large & complex shapes

Magnetic Particle Testing

Magnetic particle testing is a non-destructive test method, which can be used to inspect a variety of ferromagnetic components and products. These include castings, forgings and weldments. • Simple, fast, and reliable operation Versatile to locate both surface and near surface • No size limitations for parts to be tested • Indication are directly visible on the surface

Hardness Testing

Hardness testing enables you to evaluate a material's properties, such as strength, ductility and wear resistance, and so helps you determine whether a material or material treatment is suitable for the purpose you require.

Positive Material Identification

Positive Material Identification PMI (Positive Material Identification) testing is the analysis of materials to determine the chemical composition of a melal or alloy at particular (Usually multiple) steps of alloy manufacturing or in-process alloy installation. •Knowing the exact composition and grade of an alloy enables suppliers, plant workers, and other responsible parties in the chain of custody of components to match alloy specifications that are chosen for their specific properties such as heat resistance, corrosion resistance, durability etc. Having the right alloy in the right place is essential in places like petroleum refineries and chemical plants, because the right alloy with the right properties is often all that stands betweenasafe, efficient operation and lost time and revenue

Advanced Services

ECT/RFT/MFL/IRIS

Eddy Current testing of tubes is an effective Way of assessing the condition and lifespan of tubes, particularly in The power generation, petrochemical, chemical, fertilizer and Air conditioning industries. Eddy current testing is an advanced nondestructive testing technique using electromagnetism induction for crack detection, measurement of metal thickness, detection of metal thinning due to corrosion and erosion, determination of coating thickness, and the measurement of electrical conductivity and magnetic permeability. Eddy current testing can be used in a wide variety of test, including welding inspection, tubing inspection, corrosion detection etc.

Leak Testing

A Helium Leak Detector, also known as a Mass Spectrometer Leak Detector (MSLD), is used to locate and measure the size of leaks into or out of a system or containing device. The tracer gas, helium, introduced to a test part that is connected to the leak detector. The helium leaking through the test part enters through the system and this partial pressure is measured and the results are displayed on a meter. We offer services for Helium Leak Testing and Vacuum Box Testing.

Oxide Scale Measurement

The ID oxide scale is produced by oxidation in the Boiler Tubes. The scale build up occurs when the tubes have experienced high temperatures for extended periods of time. The formation of ID scale reduces heat transfer and results in a further increase of tube metal temperature. The increase in ID scale and the associated tube metal temperature promotes creep in the tube metal. Formation of creep results in a loss of strength at high temperature and therefore a loss in remaining life. The final outcome of excessive scale is a long term overheats failure. Our advance Ultrasonic Testing equipment and highly experienced engineer ensures accurate and reliable Internal Oxide Scale Thickness measurements.

Remote Visual Inspection

REMOTE VISUAL INSPECTION Industrial videoscopes are commonly used for visual inspection of inner areas of various infrastructure equipment as well as industrial products. Familiar examples cover a broad range from monitoring ofhome pipings or ducts of water/sewerage, gas and air conditioners to quality check of automobile components. They are also used for visual inspection of large equipment such as airplane engines and electricity generator turbines without dismantling those. Thus, industrial videoscopes play important roles to support safety and security from behind the scenes. Particularly, videoscopes are the requisite equipment for inspection of heat exchangers.

PAUT/TOFD

Phased Array Ultrasonic Testing is an advance method of NDT examination utilizing multi-element probes, which are individually excited under computer control. Both PAUT (Phased Array Ultrasonic Testing) and TOFD (Time of Flight Diffraction) are forms of ultrasonic testing (UT) that are used by NDT inspection services to evaluate assets for flaws and defects. Like PAUT, TOFD uses sound waves to detect flaws by measuring the time that it takes for the sound wave to be emitted and returned. However, the difference between PAUT and TOFD is that TOFD measures both high and low amplitude waves. That is, PAUT records only high amplitude waves that are retuming from the back of the asset, while TOFD records both high amplitude waves and low amplitude waves that deflect off of the tips of flaws and defects. Now, Phased Array Ultrasonic Testing is widely used in steel fabrication industries as an alternative method of testing in lieu of radiography testing for thick wall materials. Ability to penetrate thick sections Faster inspection rate Ability to inspect many different materials Image Data is recorded and saved.

Remaining Life Assessment

Remaining life assessment (RLA) is an important tool in securing the operational safety of aged structures and plants. RLA combined with risk based inspection can prevent unforeseen outages and failures that can have tragic and costly consequences. With RLA as part of a fitness for service (FFS) assessment the full service life of individual mechanical components can be safely utilized. The key point in determining the remaining life of a mechanical component is determining when structural integrity becomes critical due to progressive damage caused by the applicable damage mechanism(s). Due to continuous use under high temperature, pressure and critical environmental conditions, material properties are degraded. Damage due to creep, fatigue and corrosion are irreversible and essential to predict remaining life.

In-Situ Metallography

In-Situ Metallography is an on-site, non-destructive Metallurgical Technique, employed for microscopically observing and documenting the microstructural integrity of many engineering metal parts, castings, forgings, welds, brazed joints, equipment, components, boilers, pressure vessels, main steam pipes, pipelines and all type of structures.

Post Weld Heat Treatment

Post Weld Heat Treatment or PWHT must be performed after every welding in order to ensure the material strength of the part is retained. PWHT ensures the reduction of residual stresses, controlling material hardness, and enhancement of mechanical strength.

Improved metallurgical structure

Improved ductility of the material

Reduced risk of brittle fracture as ductility increases

Relaxed thermal stress due to the redistribution of residual stresses.

Tempered metal

NDT-Training & Certification

PARAS Inspection Services a leading NDT Training Provider in Ahmedabad. We provide world class NDT Training. Examination and Certification in accordance with American Standard ASNT. Our aim is to provide high quality training to the professionals to make them more competent and confident in delivering their responsibilities in the level of quality expected from the industry. We have excellent training room equipped with audio, visual power point presentation and latest NDT Instruments for Practical Training. Our faculty is highly qualified and experienced. We provide NDT Level-I and Level- II Training in Ultrasonic Testing, Radiography Training, Magnetic Particle Testing. Liquid Penetrant Testing, Eddy Current Testing, Visual Testing and Leak Testing. We took NDT training at Adani power Plant at Mundra, Tata power plant Mundra, Bhuj boiler, Ratnamani pipes & tubes, Indus University & etc.

NDT LEVEL-III Consultancy

We provide NDT Level-III Consultancy for preparation and approval of NDT written practices as per ASNT recommended practice SNTTC-1A or CP 189, preparation and approval of NDT procedures for various inspection methods as per applicable National or International Code and Standard, technical assistance in purchasing and installation of NDT equipment or system at client'sworks and operator training to run the equipment or system, periodic evaluation and recertification of NDT Level -I and Level -II certificate as per guidelines of ASNT recommended practice SNT-TC-1Aor CP 189.

Third Party Services

Ready to Get Started?

Contact us today to discuss your quality testing and inspection needs. Our experts are ready to help you ensure product excellence.